2.4. Weaving and arc sensing condition setting with commands

2.4. Weaving and arc sensing condition setting with commands

(1) Necessity of the function

Weaving and arc sensing conditions are included in the weaving condition file. The number of condition files is limited to 32, and the conditions may not be automatically changed during the operation. However, using more than 32 conditions or changing some of them automatically will be required.

In this case, commands may be used to change weaving and arc sensing conditions.

The changed conditions with this command are valid only in the corresponding weaving section.

(2) How to use commands

l In the manual mode, insert commands as follows.

[Enter command] à [F7: Substitution] à[PREV/NEXT] à Insert WEAVCmd à Select a weaving parameter

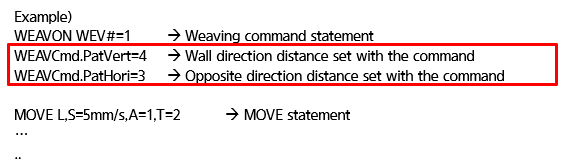

l Commands are entered as follows.

WEAVCmd.[Weaving parameter]=Value

l The input values of the commands are limited to the same ranges of condition settings of the condition files. However, StickOut and FdTrkClr elements are not the weaving and arc sensing conditions.

l Parameters that are not separately designated with commands use the conditions set with the WEAVON command.

l The following table shows whether the setting value is applied to the function of each element of WEAVCmd.

Variable name | Right after WEAVON command | Weaving operation without arc sensing | Weaving operation with arc sensing | Continuous change of welding conditions |

Type | Apply | Apply | Apply | Apply |

Freq | Apply | Apply | Apply | Apply |

PatVert | Apply | Apply | Apply | Apply |

PatHori | Apply | Apply | Apply | Apply |

PatAngle | Apply | Apply | Apply | Apply |

PatWalDi | Apply | Apply | Apply | Apply |

OffsetAng | Apply | Apply | Apply | Apply |

FwdAngle | Apply | Apply | Apply | Apply |

BoundLmt | Apply | Apply | Apply | Apply |

MoveTime | Apply | Apply | Apply | Apply |

Dwell | Apply | Apply | Apply | Apply |

HSMethod | Apply | Not apply | Apply | Apply |

SideSens | Apply | Not apply | Apply | Apply |

UpdnSens | Apply | Not apply | Apply | Apply |

BaseCur | Apply | Not apply | Apply | Apply |

StickOut | Apply | Not apply | Apply | Apply |

AsymSsDist | Apply | Not apply | Apply | Apply |

FdTrkClr | Apply | Not apply | Apply | Apply |

(3) Weaving parameters and details

l Type: Weaving pattern

l Freq: Weaving frequency

l PatVert: Wall direction distance

l PatHori: Opposite direction distance

l PatAngle: Basic pattern angle

l PatWalDi: Wall direction of the basic pattern

l FwdAngle: Forward angle

l BoundLmt: Boundary limit use status

l MoveTime: Time of each section with moving time

l Dwell: Time to stop weaving only with moving time

l HSMethod: How to execute up/down sensing during arc sensing

l SideSens: Left/right side arc sensing sensitivity

l UpdnSens: Up/down arc sensing sensitivity

l BaseCur: Up/down sensing reference current

By setting this value, you can set the distance between the torch and the base material. Decrease the value if you want to set a longer distance between them. Meanwhile, increase the value if you want to set them closer.

l StickOut : This value is to move the torch in the up and down directions during arc sensing. The torch height will be changed by the value entered in ‘mm’. When a + value is entered, the distance between the torch and the base material increases, and when a – value is entered, the torch becomes closer to the base material.

l AsymSsDist : Asymmetrical left/right side sensing rate

l FdTrkClr : When this variable is set as 1, the compensation distance in the direction of the welding line during arc sensing will be gradually cleared during arc sensing that proceeds in a straight line. During an arc sensing operation in which the length is long and there are many curves, this function can be used in a case where the compensation distance acquired by sensing in the previous curved section should not be used for the sensing for the next curved section.