10.1.2. Perform welding – Air gun

10.1.2. Perform welding – Air gun

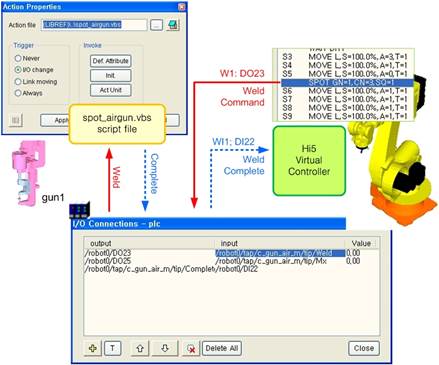

The operation of Air gun is executed by script file. Script get Weld, welding instruction signal, show the pressing movement of moving tip, and produce Complete command.

spot_airgun.vbs | For C gun. Control Air gun with signal. |

x_gun.vbs | For X gun. Control Air gun with signal and control X gun link |

These scripts need attribute settings as below.

Name | Description | |

Mx0 | Value of moving tip axis when the value of Mx is 0 | |

Mx1 | Value of moving tip axis when the value of Mx is 1 | |

Closed | Value of moving tip axis when pressed. | |

UnitMove | Unit for the movement of moving tip (Bigger number means higher speed) |

As you can see in a picture as below, the robot produces W1 assigned output signal and is on standby.

(Assigned output and assigned input are set in System/Application parameter/SPOT welding menu by using Virtual TeachPendant.)

Set I/O connection to plc model as you can see an example as below since this signal should be entered to moving tip as Weld signal. (Set path appropriately to fit workspace configuration.)

Output | Input |

/robot0/DO23 | /robot0/tap/g_gun/tip/Weld |

spot_airgun.vbs, scripts of moving tip, do welding operation when it receives Weld signal, and then produces Complete signal. Set I/O connection to plc model as you can see an example as below since this signal should be entered to the robot as WI1 assigned input signal.

Output | Input |

/robot0/tap/g_gun/tip/Complete | /robot0/DI22 |

The VRC that was waiting moves to the next command when it receives WI1 signal. This I/O connection is the same as the operation method of Air gun in actual processes.