3.1. Inspection Items and Cycle

3.1. Inspection Items and Cycle

The inspection must be performed to maintain a high performance when the positioner is to be operated for a long duration.

Inspections are divided into daily and regular inspections, and the personnel responsible for inspections must carry out inspections according to the basic inspection cycles, as shown in [Table 3-1].

The overhaul should be carried out every 20,000 operating hours.

It is required to refer to the following items. If the inspection and adjustment methods are difficult to understand, please contact our after-sales service center (customer support department) for inquiries.

Table 3‑1 Inspection Plan, Items, and Cycle

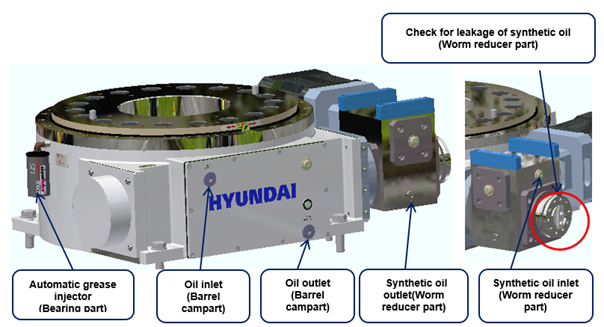

Cycles for Replacing/Replenishing Grease and Oil | |||

Classification | Replenishment Amount | Replenishment Cycle | Replacement Cycle |

Barrel cam part (Oil) | - | - | 2 years |

Worm reducer (Synthetic oil) | 20 cc | When oil leakage is found | - |

Automatic grease injector | - | - | 1 year |

Figure 3.1 Oil Inlet and Outlet

Table 3‑2 Inspection Items and Cycle

No. | Inspection cycle | Inspection items | Inspection method | Reference | Remarks | ||

Daily | 3 months | 1 year | |||||

Common for the main body and individual axes of the positioner | |||||||

1 | ○ |

|

| Cleaning of the main body | Visually checking for impurities |

|

|

2 |

| ○ |

| Inspection of the wiring | · Visually checking for damages to the cables · Visually checking the paint markings of the cable fixing bracket fastening bolts ·Visually checking for damages to the cable covers |

|

|

3 |

| ○ |

| Main bolts | Visually checking the paint markings |

|

|

4 | ○ |

|

| Motor | Checking for abnormal heat generation Checking for abnormal sound generation |

|

|

5 | ○ |

|

| Reducer | Checking for abnormal heat generation Checking for abnormal sound generation |

|

|

n If the positioner is used under adverse conditions, it is recommended to take a shorter inspection cycle to ensure the performance of the positioner.

n Inspect all visible cables, and replace any damaged cables.

n Check the fastening torque of the key bolts in [Table 3-3].

n Check for any abnormal sound in the automatic or teaching mode to check the power transmission system (motor, reducer, etc.) for abnormalities.