1.6.2. Placement of the Robot and Peripheral Devices

1.6.2. Placement of the Robot and Peripheral Devices

Must place the robot and peripheral devices in the following ways. |

(1) To connect the primary power of the controller or peripheral device, you should first check if the supply side power is off before proceeding with the work. There is a risk of electric shock because high voltage such as 220 V or 440 V is used as the primary power source.

(2) Attach the [Do Not Enter During Operation] sign to the entrance gate of the safety fence and inform the workers of its intent.

(3) Place the controller, interlock panel, and other operation panels in a way that they can be operated outside the safety fence.

(4) When installing an operation stand, attach an emergency stop button to it as well. It should be made possible to stop the robot in an emergency situation at any location from which the robot is operated.

(5) Make sure that the wires and pipes for the manipulator, the controller, the interlock panel, and the timer are not caught on the feet of workers or directly stepped on by the forklift. There is a risk of an accident in which workers are electrocuted or wires are disconnected.

(6) Place the controller, the interlock panel, the operation stand, etc., in a location from which the movement of the manipulator can be seen sufficiently. There is a risk of a major accident if the robot is malfunctioning in a location where you cannot see the operation of the robot or if a worker is carrying out works in such a place.

(7) If the operation area required for the robot is narrower than the area where the robot can operate, you should limit the operation area of the robot. Limiting it can be performed via soft limits, mechanical stoppers, etc. Even when the robot operates outside the limited area because of an abnormal operation such as improper operation of the robot, the robot will automatically stop because of the operation area limit function (refer to the Manipulator Maintenance Manual.)

(8) During welding, spatter may fall on the workers or surroundings, causing a burn or fire. Install light shields, covers, etc. to an extent where the movement of the robot body can be seen sufficiently.

(9) In the case of a device that shows the auto or manual mode of the robot, install the device conspicuously so that the operation status can be recognized even from a little distance away. A buzzer or alarm light is useful for the staring of the auto operation.

(10) Make sure there is no protruding part on the peripheral systems around the robot. If necessary, cover the systems with a cover, etc. In general, an accident may occur when a worker touches one of the systems, and a large-scale accident may occur when a worker falls by being surprised by a sudden movement of the robot.

(11) Please do not design a system that requires putting your hand inside the safety fence to carry in or take out workpieces. Otherwise, there is a risk of an accident of being crushed or cut.

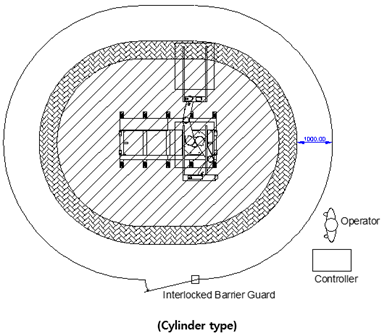

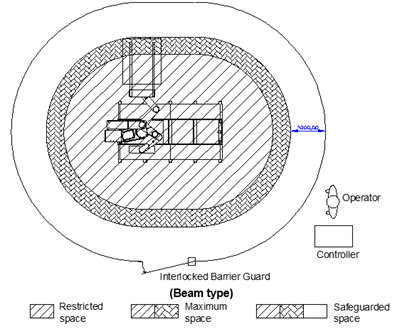

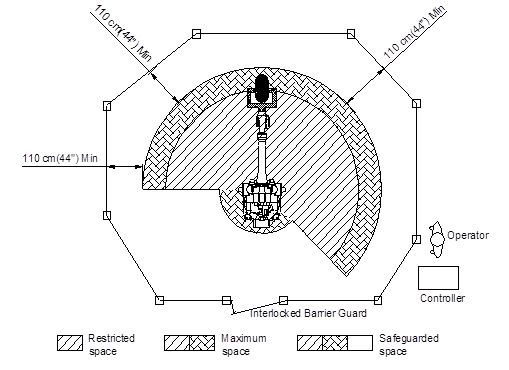

Figure 1.3Placement of the Peripheral Systems of the LCD Robot, and the Workers

Figure 1.4Placement of the Peripheral Systems of the Industrial Robot, and the Workers