8.2.1. Disconnecting the gas spring assembly unit

8.2.1. Disconnecting the gas spring assembly unit

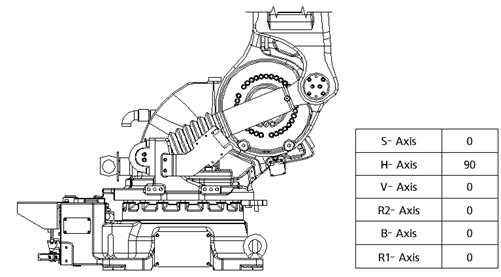

The H axis must be at the angle and posture as shown in [Figure 9.1] during the work of disconnecting the assembly unit. In this posture, the compressive force of the gas spring is minimized, allowing the assembly unit to be disconnected from the robot. Therefore, even if the gas spring assembly unit is disconnected from the main body, the compressive force will be kept in balance by the spring, helping minimize the risk factor during the disconnection process.

If the disconnection work is carried out to dispose of the gas spring or perform internal maintenance works, please carry out the disconnection work after completely removing the gas in compliance with the procedures of “9.3. Releasing the gas of the gas spring.”

Figure8.1 Posture for disconnecting the gas spring

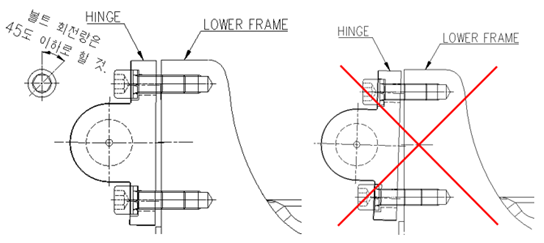

Caution ü When disconnecting and assembling the gas spring assembly unit, fasten or loosen the bolt of the hinge by rotating the bolt 45 degrees or less alternately between the upper and lower bolts so that the hinge will not be tilted excessively, as shown in the figure below. Excessive tilting of the hinge will cause damage to the bolt screws, and such a damaged bolt screw will damage the tap of the lower frame, making it difficult to perform the disconnecting and assembling process. ü The shape of each part such as hinge can be changed according to the mass production design. |

[Bolt rotation amount 45 degrees or below: Approved] [Bolt rotation amount 45 degrees or above: Not Approved]