1.1. What is a welder interface?

1.1. What is a welder interface?

It is an integrated control function that enables the Hi5a controller to perform data input, monitoring, and data management of the spot welder using DeviceNet communication between the Hi5a controller and the spot welder.

The robot controller and spot welder are configured as a unit, making it possible to perform data editing and file management in the welding program by using the Hi5a controller teach pendant. The teaching pendant of the robot controller enables the robot controller to perform the main functions of the spot welding controller, such as welding schedule programming, stepper programming, welding result monitoring, and history file.

In other words, the welder interface provides a user interface that allows the robot teach pendant to perform the functions of the teaching box, which is the control panel of an independent welder.

The welder interface makes it possible to display and monitor the welding results, various signals, and the status of errors and faults.

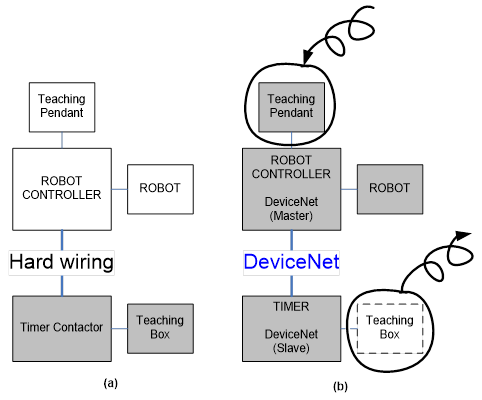

Figure 1.1 (a) Spot welding system separated / (b) Spot welding system integrated

The robot controller and welder communicate through DeviceNet. The robot controller is configured as the master and the welding controller as the slave.