2. Functions

The following description is about the function based on the assumption that the S axis motor is replaced.

(1) Designate the new program (101.JOB) and carry out teaching for S1 [Checkpoint approach] and S2 [Origin checkpoint. Only the S axis rotates compared with S1] in order to approach to one point of a firmly fixed tool or a jig or a peripheral system.

S1 [Checkpoint approach]

| S2 [Origin checkpoint. Only S axis rotates compared with S1]

|

(2) After the S axis motor is replaced, it is needed to manually operate the S axis to approach near the encoder correction position prior to replacement. After that, carry out encoder correction for the S axis in the System / Robot parameter / Encoder correction screen.

(3) Move to S1 by manually operating the taught program (101.JOB) and then to S2 while carrying out teaching for S3 [Origin checkpoint. Only S axis rotates compared with S1] when the position is the same as prior to the replacement.

S3 [Origin checkpoint. Only S axis rotates compared with S1]

(4) The encoder correction value for the S axis will be calculated automatically.

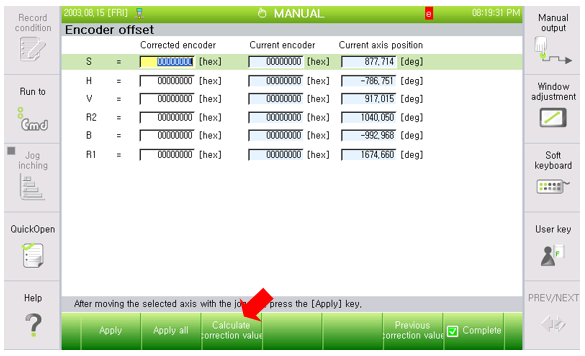

1. Enter the System / Robot parameter / Encoder offset screen.

2. Move the cursor to the S axis and press [F3: Calculate correction value].

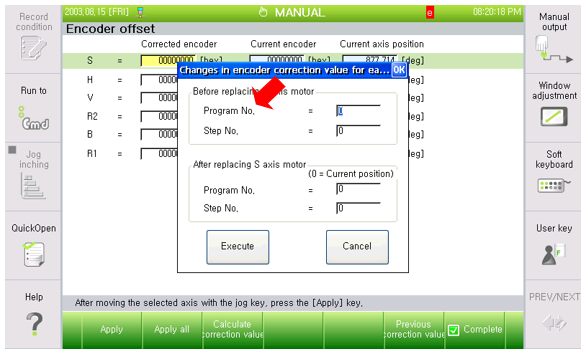

3. Set 101 as the number of the program “prior to S axis motor replacement” and 2 as the step number. Set 101 as the number of the program “after S axis motor replacement” and 3 as the step number. Then, press the [Execute] button.

(※ If the number of the program “after S axis motor replacement” or the step number is 0, the encoder correction value will be calculated based on the current robot position on the S axis.)

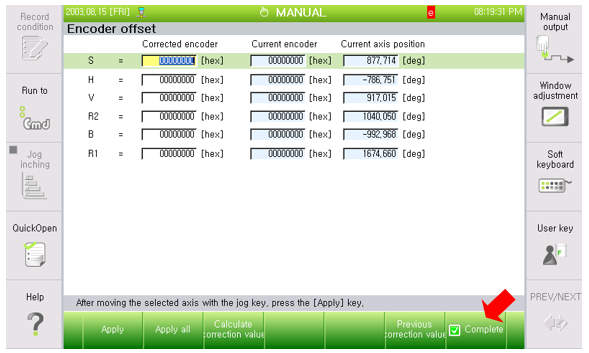

4. The encoder correction value calculated on the S axis will be displayed on the screen. When [F7: Complete] is pressed, the corrected encoder value will be reflected.

5. When the position moves to S2 of the taught program (101.JOB), it is needed to check the position is the same as prior to the replacement of the motor.