2.1.3. Dialog box for load validation

2.1.3. Dialog box for load validation

(1) For using the industrial robot with optimal performance, it is necessary to input the correct load. The function of the gas spring pressure check can be used normally when the correct load is set.

(2) Enter the dialog box for “Load validation” by clicking “F1: Tool load validity” in the dialog box for the “function of gas spring pressure check.”

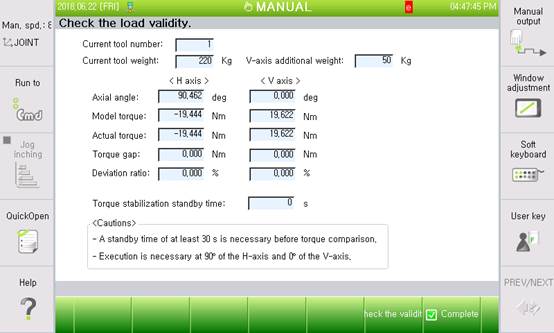

Figure 2.2 Dialog box for load validation

(3) Check whether the current tool weight and the additional weight values are normal.

(4) By manipulating the jog, move the H-axis to 90° and the V-axis to 0 ° positions. (They may be set within +/- 1° of the target angle.)

(5) Wait for longer than 30 seconds at the motor on and the stop state until the torque is stabilized. Depending on the function setting of the robot, the waiting time may be extended to 1 minute.

(6) When the waiting time becomes 0, the torque difference and the error ratio will be displayed.

(7) Carry out “validation” by clicking the F6 key. When it is determined that the load is valid, the “Tool load validity” display item in the dialog box for setting the gas spring pressure check will be changed to the “checked” status.

(8) If the error ratio exceeds 20%, and if the torque difference is equal to or more than 2 Nm occurs while the model torque is equal to or less than 10 Nm, it will be determined that the tool load is not valid. In this case, enter the additional weight of the V-axis correctly, and carry out load estimation again.