7.2. Operation

7.2. Operation

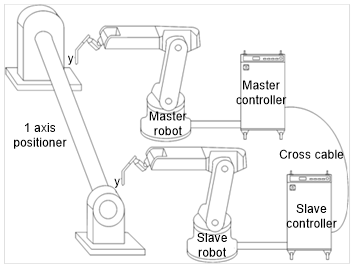

As shown below, if two robots are performing welding for one positioner at the same time, the cooperation control arc function will be used. In this situation, if the two robots do not carry out welding simultaneously, defective welding could be caused.

Figure 7.2 Conceptual diagram of cooperative controlled arc welding function

The following is an example of the actual application:

(1) In case the master robot number is 1 and the slave robot number is 2, the master side controller setting can be done as follows.

n State output port: GE4 (Select one among 1~4)

n State input port: GE8 (Match with slave size state output port)

(2) Slave side controller setting can be done as follows.

n State output port: GE8 (Select one among 5~8)

n State input port: GE4 (Match with master side state output port)

n Enable the remote WCR signal.

(3) In the automatic mode, make two robots fulfill the ARCON command simultaneously under the cowork control.

(4) If the two robots succeed in simultaneous arc ignition, the positioners and the robots will carry out welding while moving.

(5) If one robot fails the arc ignition, the other robot will stop arc and both robots will execute the retry function simultaneously. When two robots succeed the arc ignition simultaneously, two robots will move normally.

(6) If one of the two robots stops the arc welding due to stoppage or an error during the welding work, the other robot will also cease the arc welding work. When started again after the cause of the error is removed, the two robots will perform the overlap function together before enter the stage of performing the main welding work again.

(7) When only arc welding work on one side is finished normally during welding work by ARCOF, arc welding work on the other side will not be influenced by this.