7.1.1. Drawing arc sensing wave form

7.1.1. Drawing arc sensing wave form

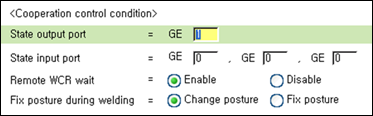

The conditions of arc welding may be set by clicking the “[QuickOpen]” key under the ARCON command. In the case of a system for which cowork control is set, the “cowork control condition” setting items will be displayed in the welding condition dialog box as shown in the figure.

Figure 7.1 Cowork control condition items in the welding condition dialog box

n State output port: Set the GE port from which arc welding signals will be outputted for a cowork-controlled arc welding.

n State input port: Set the GE port to which arc welding signals will be inputted for a cowork-controlled arc welding. The arc welding signals can be inputted from a maximum of three cowork robots.

n Remote WCR: Set whether to check the welding current relay (WCR) of the cowork robots while checking the WCR signal input for the arc welding process.

n If 0 is set for a port, the input and output ports set for 0 will not be used.

n Details of the GE signal by bit

Bit 0(ArcOn): To be set as ‘1’ when the torch is on as the ARCON command is executed.

Bit 2(WCR): To be set as ‘1’ when there is an input of WCR of the robot as set.

Bit 3(Retry): To be set as ‘1’ until retry ends while the retry function is being performed.

Bit 4(Overlap): To be set as ‘1’ until overlapping ends while the restart function is being carried out.

Bit 5(Dry Run): In the dry run in which the robot moves without making an actual welding, the bit will be set at 1.

Bit 6(ArcSt): To be set as ‘1’ until the main moving operation is handled after the arc is turned on. The retry state is included.

n Position fixation during welding: This function prevents rapid changes in the position of the slave robots during cowork-controlled welding. When this function is enabled, the position of the torch will be fixed, and only the TCP position will change.

l Cowork robots of different robot numbers will have different port numbers that can be set as I/O ports. Refer to Table 7-1, “I/O Area by Robot Number.”

l Cowork control cannot be made in the welding section of a dry run (welding simulation) because remote WCR signals will not be transmitted. Therefore, disable this setting for a dry run.

l Welding with a disabled remote WCR signal may lead to a wrong synchronization in the welding section.