2.7.2. Operationtype

2.7.2. Operationtype

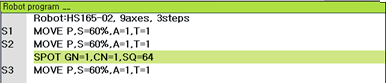

To execute tip dressing operation by using the servo-gun tip dressing condition, the welding sequence number of SPOT command should be assigned to 64, as shown below.

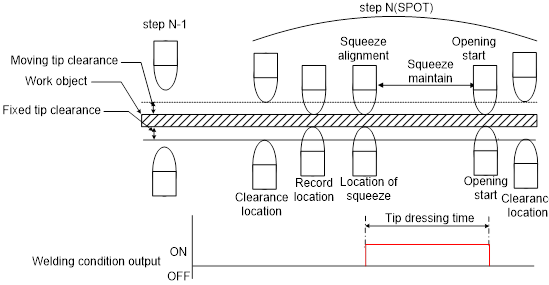

(1) From the N-1 step location, the moving tip moves to location that is at a distance equal to the moving tip clearance from the record location, and the fixed tip moves to location that is at a distance equal to the fixed tip clearance from the record location.

(2) Move to the record location of step.

(3) The moving tip carries out squeeze with the squeeze force registered on the welding condition. When the squeeze alignment is achieved, the welding condition signal will be displayed at that location. At this time, the output of the welding execution signal together will be determined according to the “Welding signal output” from the tip dressing condition.

(4) After the time to register tip dressing has passed, both the moving tip and fixed tip will be opened sufficiently for clearance.

(5) Continue to the next step.