1.1. Overview

1.1. Overview

The OLP (Off-line programming) is designed for planning jobs in simulation environments and minimizing additional teaching jobs in the actual working place. Theoretically, the program created in the OLP may be downloaded to substitute real work. However, in real working conditions, various tolerances exist in terms of robot’s accuracy, accuracy of the robot’s installation positions and installed work piece positions, etc. Those tolerances are the reasons why the OLP applications may not be applied in worksites as they are.

Therefore, it is needed to correct the position calculated in the OLP to fit in the real job position, which is called ‘OLP installation tolerance calibration.’ The function may correct the OLP installation tolerance by performing the teaching operation to the CAD-based base program created in the OLP and the robot found in the same location, and by creating the formula which converts the difference between the two coordinate systems.

The function’s correction method uses the user coordinate system. Users teach the robot program to be converted into the user coordinate system. When the base program created in the OLP and the program created by the user’s teaching are put, the conversion value between the two programs is added as the conversion value of the pre-set user coordinate system. As a result, the job position of the program that has been taught to change into the user coordinate system is corrected to match the real workpiece position.

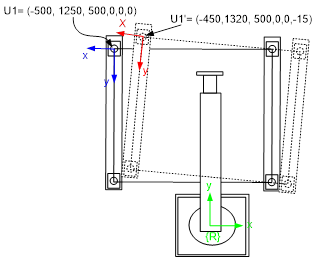

An OLP-based workpiece 1 is located at U1 as shown in the following figure, but if it is positioned at U1’ during the actual installation, differentials occur between the two coordinate systems: -50 mm, 70 mm, and 0 mm in the X, Y, and Z directions; 0, 0, and -15 degrees in the Rx, Ry, and Rz directions, respectively. The calibration function compensates for the installation tolerances by computing the U1’ instead of the U1.

The Hi5 controller supports the 10 user coordinate systems. So, each workpiece may be compensated for the installation tolerance based on each of the set user coordinate system.