4.2.1. PC Side Loopback Test Method

4.2.1. PC Side Loopback Test Method

Figure 4.6 RS-232C Communication Setting Dialog Box

(1) To test whether the RS-232C connection is normal, first open the communication setting dialog box and press the button to connect the communication. When you press the

button, the following RS-232C communication test dialog box will be displayed.

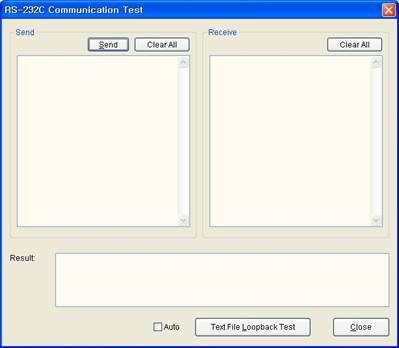

Figure 4.7 RS-232C Communication Test Dialog Box

Table 4‑1 RS-232C Communication Test Dialog Box

Send group box | Send button | This sends the text entered in the send edit box to RS-232C. (Only the first 500byte is sent.) |

Clear all button | This deletes all the text in the send edit box. | |

Edit box | This is where you enter the text to send. For text file loopback test, this shows the text that will be transmitted. | |

Receive group box | Clear all button | This delete all the text in the receive edit box. |

Edit box | This displays the text received in RS-232C. | |

Test result edit box | This shows the result of the text file loopback result. Byte sent, byte received, comparison, location and content of discrepancy etc. will be displayed. | |

Auto checkbox | Select whether to automatically repeat the text file loop back test. | |

Text file loopback test button | This runs the text file loopback test. The test reads the long text data from the internal text file, sends the text to RS-232 and compares the received data through loopback. Data sent and received are displayed respectively in the send and receive edit box. | |

Close button | This closes the RS-232C communication test dialog box. | |

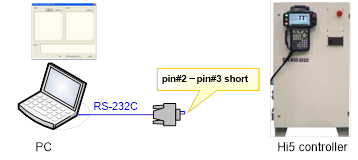

(2) You can check whether the selected COM port from the serial port of the PC is operating normally as follows. First short circuit the #2 and #3 pin of the connector of the cable installed in the COM port of the PC as shown in [Figure4.8].

Figure 4.8 PC Side Transmission Short Circuit

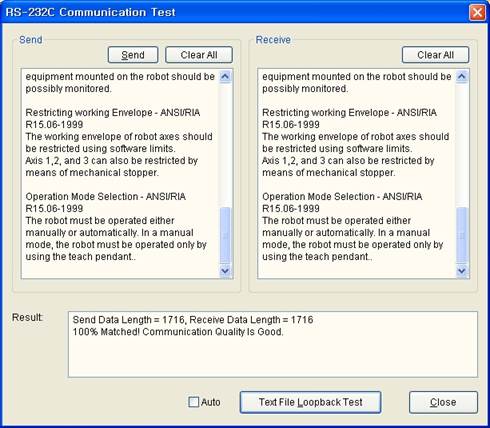

(3) When you press the Text File Loopback Test button, the internal text will be transmitted, and the content will be shown in the edit box. The result is normal if it is shown as [Figure 4.9].

Figure 4.9 Text File Loopback Check

(4) The conclusions according to the test results are shown in [Table 4-2] as shown below.

Table 4‑2 PC Side Text File Loopback Test Result

Result | Conclusion (Estimated cause) |

Data shown in the receive edit box is the same as the data sent and the test result shows 100% Matched! | Operation of COM port of PC is normal |

When there is no data in the receive edit box. | - Cable disconnected. - Cable incorrectly connected to a different COM port on PC. - COM port error on PC - Pin #2 and #3 not short circuited. - USB-Serial product (If used) setting error or defect |

The data in the receive edit box is different from the data sent and data is partially damaged. | - Partial defect in send/receive function of COM port of PC. Check for H/W error. - USB-Serial product (If used) error or poor performance |

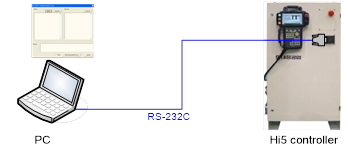

(5) You can check whether the serial communication connection to the robot controller is normal as follows. First connect the robot controller to the COM port of the PC through the serial communication cable as shown in [Figure 4.10].

Figure 4.10 RS-232C Connection Between PC and Controller

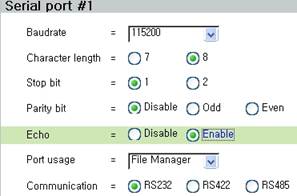

(6) From the Teach Pendant of the robot controller, select 『[F2]: System』 → 『2: Control Parameter』 → 『3: Serial Port』 → 『1: Serial Port #1』(Or, 『2: Serial Port #2』) screen and set up so that the communication parameter aligns with the PC side, and set the “Echo” to <Enable> as shown in [Figure 4.11].

Figure 4.11 Set Serial Port “Echo” to <Enable>

(7) When you press the Text File Loopback Test Button and internal text file will be transmitted and the details will be shown in the edit box. The conclusion based on the test result is shown in [Table 4-3] below.

Table 4‑3 PC –Controller Text File Loopback Check Result

Result | Conclusion (Estimated cause) |

Data received in receive edit box is printed as is but the test result is shown as 100% Matched!. | Serial connection between the robot controller and the PC is normal. |

No data is shown in receive edit box. | (When the loopback test on PC side is normal,) - RX and TX of cable is incorrectly connected. - Cable is incorrectly connected to a different COM port of the robot controller. - COM port error of robot controller. - Serial cable within robot controller cabinet is disconnected. |

The data in the receive edit box is different from the data sent and data is partially damaged. | (When the loopback test on PC side is normal,) The transmission function of COM port of the robot controller has partial error. Need to check for H/W error. |

(8) After the test, set the “Echo” of the Teach Pendant serial port screen back to <Disable>.