4.4. Teaching for Arc Welding and Sealing (Jigless Cooperation Control Option)

4.4. Teaching for Arc Welding and Sealing (Jigless Cooperation Control: Option)

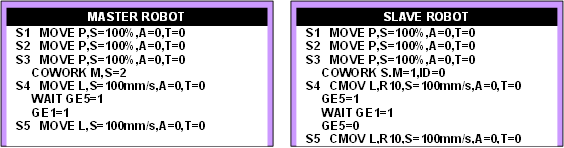

(1) After setting the manual cooperation robot role of master and slave to ‘individual’, teach the COWORK start step for the individual step and insert the COWORK command.

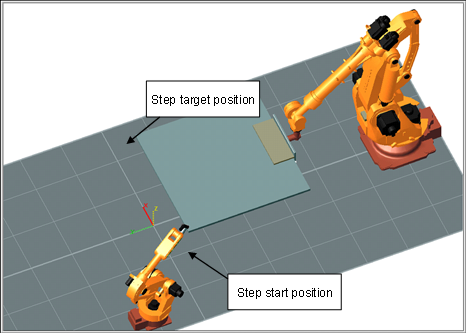

Figure 4.4 Step start and target position

(2) Change the role of master and slave to its role in manual cooperation condition.

(3) Operate the master with jog operation and the slave will follow. Record the master step in the desired recording position.

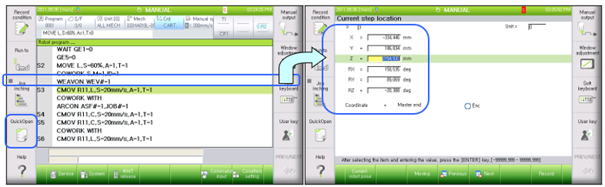

(4) The slave needs to be turned into the CMOV record mode by using the Shift+User keys or the R351,3 command. The robot role displayed at the top right of the screen turns from green to grey.

(5) Jog operate the slave robot to the target position and press the ‘REC’ key.

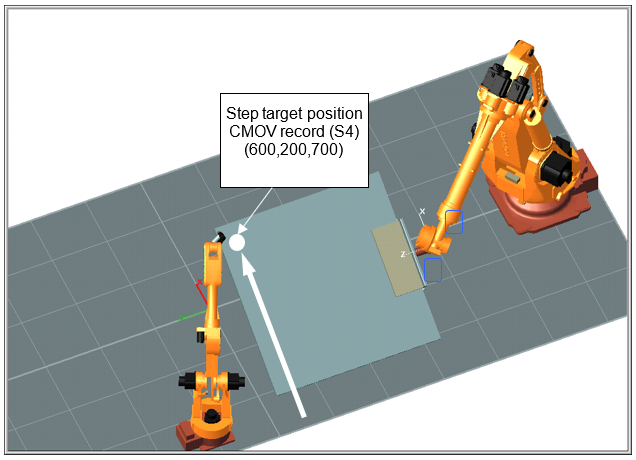

Figure 4.5 Step target position CMOV record

CMOV is recorded to the slave. The recording position of CMOV is based on the master tool end effecter coordinate. Press the QUICK OPEN to check and edit the recorded coordinate position.

The coordinate recorded at this time is to be displayed as ‘Master end’.

(6) Multiple CMOV steps can be recorded by moving the slave while applying the same manner.

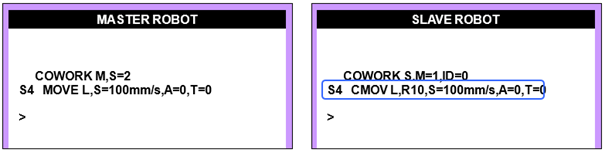

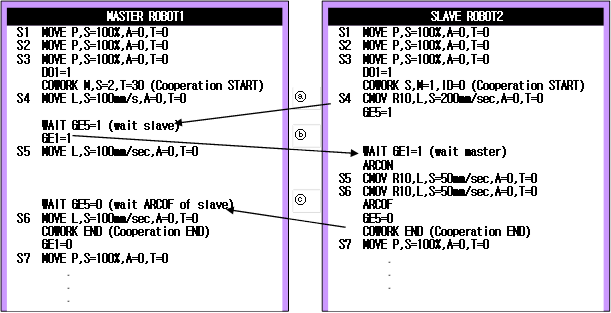

(7) But because the moving plan for recording step is executed individually between the master and slave, the time reaching the target position is different. Therefore, in order to align the timing of master MOVE position and slave CMOV start position in the collaborative zone, mutual interlock method is used with HiNet I/O.

(8) For example, to synchronize the starting point of step 5 (S5) of master and slave, method of checking whether they arrived with GE or DE parameter is used.

※ If the above method is used, the master and slave robot checks each other whether they have arrived at step 4 (S4) and moves to step 5 (S5).

(9) When the cooperation operation is completed, the COWORK END command is inserted to both master and slave to complete the cooperation control teaching.

The whole program explained above can control the timing such as ⓐ, ⓑ and ⓒ to control the timing of cooperation control, as shown below.

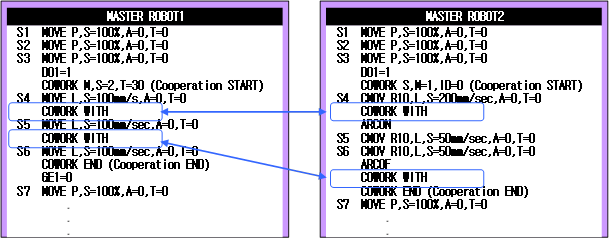

※ Programming method using COWORK WITH command

The COWORK WITH command is to be used to synchronize the positions between the master and slave while the cooperation control (Between COWORK~COWORK END) is in progress.

If the COWORK WITH command is met in the middle of the cooperation control, it is required to wait until all the cooperating robots reach the COWORK WITH condition. Accordingly, the above program can be changed according to the following method.

You can easily synchronize the starting position of cooperation between master and slave by using the COWORK WITH command as shown above.

※ Reference

l Mutual interlock in cooperation control using HiNet can be composed in different ways from the above method.

l You can check the CMOV record position of slave according to the master position by using the step forward/backward function.

l For the contents on HiNet I/O, please refer to chapter 6.

Caution

l To use the weaving operation of CMOV, reference PREF setting must be recorded within cooperation control zone (COWORK~COWORK END).

l CMOV trace seam-tracking function using the laser vision sensor is not supported.

l COWORK WITH command must be used for same number for both master and slave in the cooperation control zone (COWORK~COWORK END).