1.6.2. Placement of Robot & Peripheral Equipment

1.6.2. Placement of Robot & Peripheral Equipment

Please make sure that robot and peripheral equipment should be arranged by following method. |

(1) In case of connecting primary power of controller or peripheral devices, please work after checking whether supply power has been deleted. There is a possible danger of electric shock because the high voltage such as 220V and 440V is used as its primary power.

(2) Post a sign [No enter during operation] up the safety fence gate, and inform the operators of its purport.

(3) Arrange such devices as controller, interlock panel, and other manipulation panels to be handled outside of the safety fence.

(4) When installing operation stand, install the emergency stop button on the stand. Make sure that stopping in an emergency situation can be initiated from any place from which the robot is operated.

(5) Make sure that the robot manipulator and the wiring and piping of controller, interlock panel, and timer should not be placed in the way of operator's working range so that they would not be directly stepped on by FORK and LIFT. Otherwise, the operator may suffer electrocution or the wire may suffer disconnection.

(6) Place the controller, interlock panel, and handling stand within the sight of robotic performance. It may cause a major accident to operate the robot while the robot is malfunctioning in an area where the robot’s activity can not be observed, or while the operator is working on it.

(7) Restrict the robot's working envelope by using the soft limits and the mechanical stopper if the necessary working envelope is narrower than the robot’s workable envelope. When the robot is to move beyond the restricted envelop due to abnormal operation, such as the robot being handled in a wrong way, the robot will be stopped automatically in advance thanks to the function that restricts the workable envelop.

(8) During the welding work, spatter could fall down to workers or the workers could be injured by burning, or fire could break out. Install such devices as a glare shield or a cover in the full sight of robot's working envelope.

(9) Make sure that the device indicating the robot's running condition, whether automatic or manual mode, can be noticeable even from a slightly distant location. In the case of automatic start-up, a buzzer or a warning lamp will be useful.

(10) Make sure that there is no projecting part in the robot's peripheral equipment. Cover it, if necessary. It usually could cause an accident if the operator comes in touch with it. And it may cause a major accident when the operator tumbles while being astonished at the sudden movement of the robot.

(11) Don't make the system designed to allow the workers to carry the Work in and out using their hands through the safety fence. It could be a cause of accident associated with compressing or amputating.

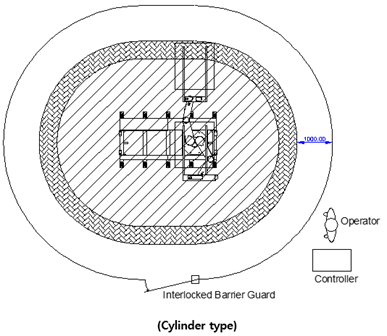

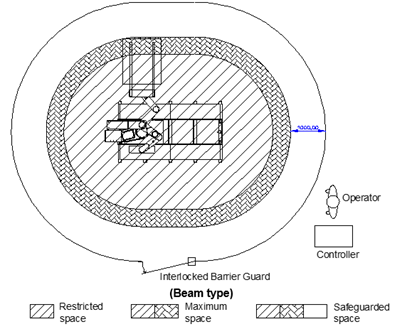

Figure 1.3 Arrangement of LCD robot peripheral devices and workers

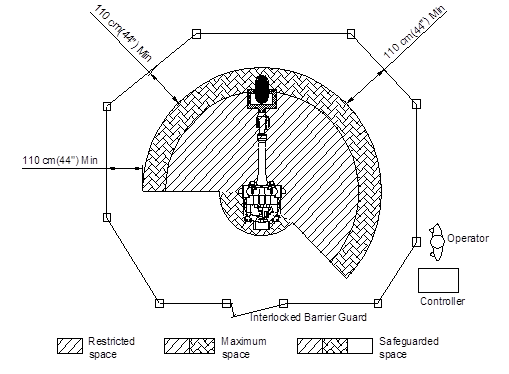

Figure 1.4 Arrangement of general robot peripheral devices and workers