4.5. Checking the timing belt

4.5. Checking the timing belt

Small robot HA/HH series has parts where the timing belt is applied on the operating assembly of the wrist axis.

For the operating assembly of the timing belt, check the tension of the belt after every 1,500 hours and when there is vibration/noise on the belt. If the tension of the timing belt is not appropriate, it may have a severely negative effect on the performance of the robot.

n Check the timing belt of R2, B and R1 axis

① Turn off the power.

② Take off the cover.

③ Measure the tension of the belt using a tension meter

④ If there is no tension gauge, press the center of the belt length to the indicated tension value and check the amount of compression.

⑤ If it doesn’t match the proper amount of pressing or tension, loosen the motor base bolt a little.(Press amount : R2 axis -2.1mm, B axis-3.5mm, R1axis-2.3mm)

⑥ Set the tension of the timing belt.

⑦ Tighten the motor base bolt. (75kgf·cm)

⑧ Assemble the cover.

⑨ Turn on the power.

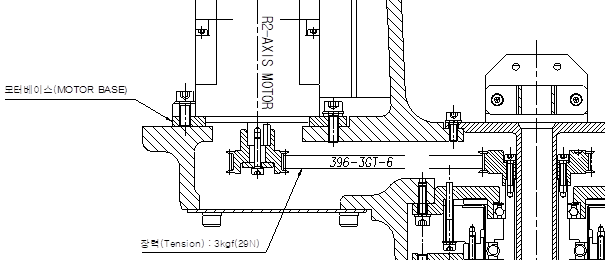

Figure 4.3 Location to check the tension of R2 axis timing belt

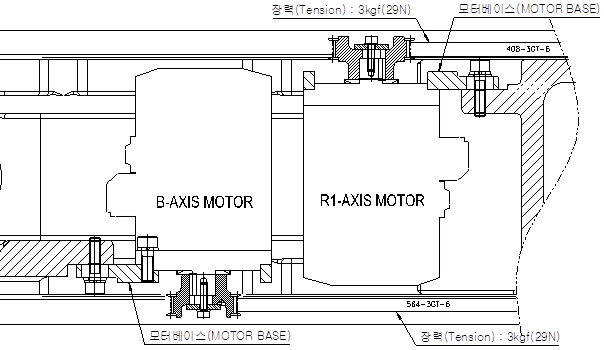

Figure4.4 Location to check the tension of R2 and B axis timing belt