9.1. Outline of function

9.1. Outline of function

Detailed setting of exclusive functions of arc such as weaving, retry/restart features of welding machine as well as welding-related conditions including voltage, current if teaching program for arc welding work. In addition, there is also a case of checking position of step or auxiliary point basically. Quick Open function is function to easily and rapidly such condition setting and position check with one-stroke of key manipulation.

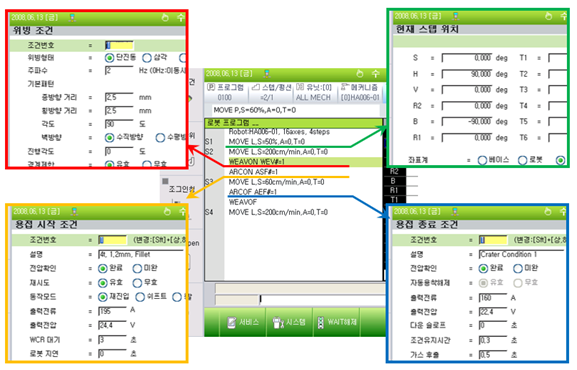

For example, contents equivalent of condition number currently used in command of various welding start conditions if pressing the [Quick Open] key, when the cursor is located at ARCON command that plays role of Arc On function. You can check or change details of welding start conditions from this screen. In addition, where other condition files exist in relation with the relevant condition files, you can directly move to there. In other words, this is function to easily and rapidly check, change detailed contents such as conditions files related with specific command or step position.

Figure 9.1 [Quick Open] function

Related files or detailed contents are displayed on the screen if pressing the [Quick Open] key in specific command. Press the 『[F7]: Record』key to exit after saving, and press the [ESC] key to exit without changing.

Table 9‑1 Contents appearing when pressing the [Quick Open] key in command

Command sentence | File, contents | Detailed contents |

MOVE | Step position | Current step position or global pose parameter X Y Z (mm), Rx Ry Rz (°), T1~T10 Unit, Coordinate, Robot configuration |

REFP | Reference location | |

CALL | Called program | You can open to check or edit the applicable program. |

JMPP | ||

Replacement statement | Variable check and change | You can monitor and change the applicable variable depending on the variable type of the replacement statement. V%, V!, V$, P, R, LV%, LV!, LV$, LP, LR, system variable etc. |

ARCON ASF#= | Arc start condition file, Arc auxiliary condition file, welder condition data file | l Welding start condition Condition number, Description, Voltage Confirm, Retry, Operation mode, Output current, Output voltage, WCR wait time, robot delay time, etc. l Welding auxiliary condition -Retry: Count, retract time/speed, Reentr./Path Dist., shift distance, speed, current, voltage. -Restart: Count, Overlap length, moving speed, welding current, voltage, current -Overlap condition setting (while in welding): Arc, gas, wire and coolant l Arc welder condition Welder number, name, explanation, power control mode, wire diameter, protruding distance, stick detection time, arc off detection time, etc. -Current characteristics: Polarity, command value(V), measured value (A), and calibrated value -Voltage characteristics: Polarity, command value(V), measured value (V), and calibrated value |

ARCOF AEF#= | Crater condition file, Arc auxiliary condition file, welder condition data file | l Welding end condition Condition number, description, voltage confirm, output current, output voltage, down slope, Condition hold time, gas postflow, l Welding auxiliary condition Auto stick recovery: count, current, voltage, and delay time. |

WEAVON WEV#= | Weaving condition | l Weaving condition Condition number, weaving type, frequency, basic pattern, forward angle, boundary limit, moving time, timer l Arc sensing condition Arc sensing, side sensing start cycle, height sensing start cycle, voltage coefficient, tracking distance per sampling, etc. |