5.1. Environment setting

5.1. Environment setting

The spot welding environment should be set in the manner that the system will carry out appropriate operations according to actual circumstances.

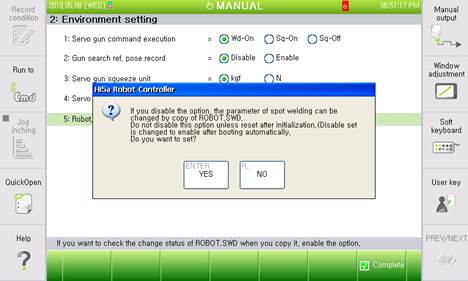

(1) Servo-gun SPOT command execution type

If the gun type is servo-gun, the execution of squeeze and the output of the welding signal can be prohibited when executing SPOT command, regardless of welding sequence setting. Therefore, this function can be useful for confirming the teaching location. The sequence of spot welding will be executed according to the following setting conditions.

Output type | Description |

Wd-On | Execute all welding sequences assigned to the spot welding function. clearance location → squeeze → squeeze alignment test → Welding signal output → welding complete wait → clearance location |

Sq-On | Execute the welding sequence except for the welding related signals. clearance location → squeeze → squeeze alignment test → clearance location |

Sq-Off | Squeeze operation, applied current signal output, WI wait will not be carried out. Clearance location. |

(2) Gun search reference location record

If using a gun type (Servo-gun, EQless-gun) for which the controller manages tip consumption, a reference location for calculating consumption should be determined, and actual consumption will be calculated based on this location.

n Disable:

Actual consumption will be calculated based on the determined the reference location.

n Enable:

The reference location for calculating consumption will be determined, and can be executed just one time in the beginning stage when a new tip is attached.

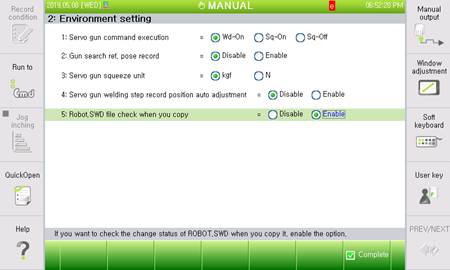

(1) Servo gun squeeze force unit

Select the squeeze force unit for controlling servo guns.

(2) Servo gun welding step record position auto adjustment

Select whether to adjust the servo gun position of the MOVE command recorded by taking into consideration the panel thickness, measured while squeezing when executing the SPOT command. This function can be used very usefully because after the teaching is completed or if the servo gun has deformation, it is possible to set the state as “Enable” and allow the work program to automatically play back once, allowing the position record to be adjusted in the optimal condition.

(3) Change test when copying the SWD file

After copying the SWD file, it is prohibited to use it for other controllers. However, it is possible to make an exception to recover the previous setting after initializing the controller. If the change test is disabled, the change test will not be performed even when the SWD file is copied. This setting will be applied only once, so the status will automatically change to “Enable” when rebooting takes place after the SWD file is copied.