1.3. Example program

1.3. Example program

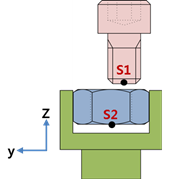

Peg-in-hole work

Movement of the robot | § Moving to S1 that is close to the hole § Moving to S2, which is the point of completing the assembly, after the SoftXYZ function is turned on § The function is turned off as the assembly is completed |

Position record | § S1: Positioning the peg close to the hole § S2: Position of the tool end for the assembly of the peg to be completed |

Limit setting | Required to set the value by differentiating between the direction that requires alignment against the recorded position and the direction that does not require such alignment. In case of the peg-in-hole work, as shown in the example, positional errors could occur in the X, Y, RX, and RY directions. It is required to control the force in relevant directions.

§ XnR: Set the movement distance necessary for work in the X, Y, RX, and RY directions. Set 0 for the Z and RZ directions to prevent any response to an external force from taking place. § VEL: Set the maximum velocity for movement that will take place through force control in the X, Y, RX, and RY directions. Set 0 for the Z and RZ directions to prevent any response to an external force from taking place. § THR:Set a threshold for individual axes in order to prevent any unnecessary movement caused by a disturbance from taking place. Use a small value considering that sensitivity will get lower as the value gets higher. |