3.2. Commands and Operation Principles of Multipass

3.2. Commands and Operation Principles of Multipass

(1) MULTIPASS command

You can save and load the sensing trajectory using the “MULTIPASS” command. This command is divided into the one for starting the saving of the trajectory and the other for ending the saving of the trajectory, based on the first parameter.

(2) Multipass trajectory saving

This MULTIPASS function makes it possible to record the count, position, and compensation amount at a designated trajectory number for a set distance during arc sensing. Multiple trajectory sets can be saved. When welding is performed alternatively for two or more welding sections to minimize the deformation of individual workpieces, various trajectory numbers can be used.

The command to start saving the data for multipass is as follows:

MULTPASS SAVE, TrjNo=[Trajectory number], SampDist=[Sampling distance]

- The trajectory number to save the compensation amount and position of the arc sensing [1-50]

- Sampling distance: This is the distance of the gap between the trajectories to be saved. [Default: 10.0 mm, Range: 5.0-100.0 mm]

- In general, save the trajectory using the default setting.

- Increase the gap if the welding section is long and exceeds the saved trajectory range.

- If there is severe bending of the welding section, set this distance short.

(3) Multipass trajectory playback

The commands for loading data and starting playback for multipass are as follows:

MULTPASS LOAD, TrjNo=[Trajectory number, Side=[Left/Right shift], Updown=[Up/Down shift], Reverse= [Playback direction], TAS=[TAS angle], WAS=[WAS angle]

- Trajectory number: Trajectory No. 1-50 to load

- Left/Right and Up/Down shift: The distance to shift from the original trajectory [Default: 0, Range: -20.0-20.0 mm]

- Playback direction: Set whether to play back the multipass in the right or reverse direction

[0: right direction is the default, 1: reverse direction]

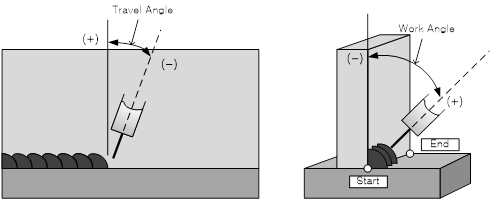

- Travel Angle Shift (TAS): Shift in which inclination occurs in the forward/backward direction [-20°-20°]

- Work Angle Shift (WAS): Shift in which the torch is inclined in the directions of both surfaces [-20°-20°]

(4) Multipass playback direction

In the case of an arc sensing multipass, the saved trajectory playback direction can be used in two ways. The playback direction should be determined and selected according to the field situation by taking into account the degree of deformation of the workpiece, the shape of the weld bead, the cycle time, etc.

l Right-direction multipass

Next pass proceeding direction: Same as the direction of the saved trajectory for which the arc sensing is performed

When it comes to the work program, the welding trajectory of the original root pass will be used.

l Reverse-direction multipass

Next pass proceeding direction: Opposite the direction of the saved trajectory for which the arc sending is performed

In the work program, the trajectory of the root pass welding is used by reversing the step sequence in the reverse order. In this case, it is required to check the trajectory as there could be confusion about the designation of the position.

(5) Left/Right and Up/Down shift

This function makes it possible to set the distance to shift from the original trajectory during playback. Because the torch weaving is perpendicular to the tool, each shift will be set, as seen below. In other words, the left and right directions will be the weaving surface, and the up and down directions will be the surface perpendicular to the weaving surface.

Figure3.4 Concept of the multipass shift direction

(6) Angle shift: TAS, WAS

This needs to be set when the torch needs to be inclined to secure quality in performing multipass welding.

The concept of individual items is as shown below:

Figure3.5 Concept of the multipass angle shift