1.5. Principle of arc sensing

1.5. Principle of arc sensing

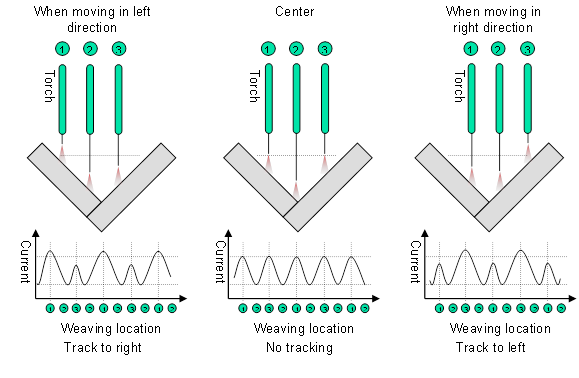

In case of weaving during arc sensing, the distance between the torch and base material exists and the resistance changes as much as the distance to change the current. That is, the welding line can be followed by calculating the distance to both ends with the current change in the weaving section, and thus, the distance can be corrected in both directions on the weaving surface. In addition, the welding start point has a few errors in the up/down direction by touch sensing, so the up/downdirection can be corrected by comparing the average current value of the weaving section center based on this value. If additionally adjusting the height during arc sensing is required, the up/down direction can be corrected based on the direct current input instead oftheaverage one.

Figure1.6 Relationship between the torch position and the current during arc sensing