5.11.1. Outline

5.11.1. Outline

The robot controller doesn't work alone, and HW and interface are required for different fieldbus communication protocols when it is a sub device of process control PLC or superior device to control a robot tool, positioner, or I/O.

Our robot controller fieldbus communication board supports the Ethernet-based fieldbus master and/or slave channel, and CC-Link IE slave and legacy communication based fieldbus(ProfiBus-DP, CC-Link) when an optional board is installed.

Channel parts and optional boards can be partially assembled and supplied according to the requirements.

l Support for Ethernet-based fieldbus

PROFINETIO-Controller (Master), IO-Device (Slave)

Ethernet/IP Scanner (Master), Adapter (Slave)

CC-Link IE Slave (When an optional board is installed)

l Support for legacy communication based fieldbus

PROFIBUS-DP (When a BD525SUBP optional board is installed)

CC-Link (C When a BD525SUB optional board is installed)

l 3 channels in total

- Ethernet/IP Scanner or ProfiNet IO-Controller or Legacy Fieldbus

- Ethernet/IP Adapter or ProfiNet IO-Device or Legacy Fieldbus

- CC-Link IE Slave

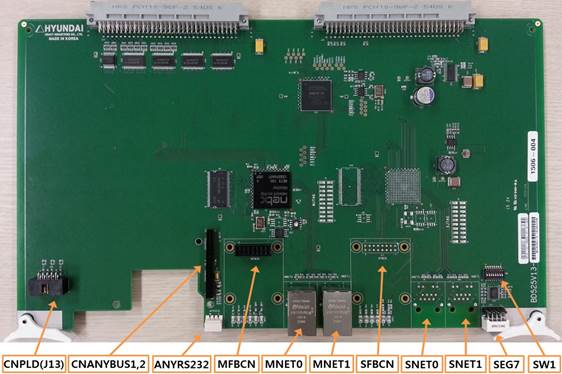

Figure 5.73 Exterior (top) of fieldbus communication board(BD525)

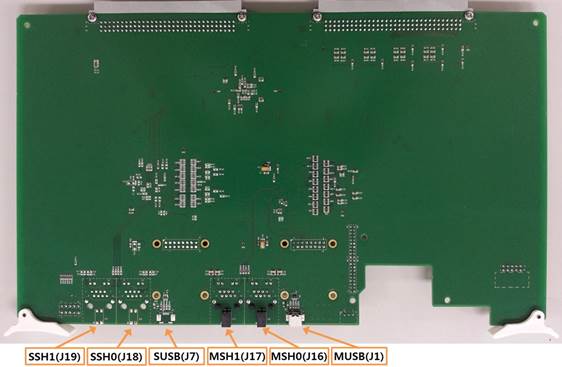

Figure 5.74 Exterior (bottom) of fieldbus communication board(BD525V13)