1.9.1. Safety Precautions for Controller Maintenance and Repair

1.9.1. Safety Precautions for Controller Maintenance and Repair

Please observe following safety countermeasures on repair and check for robot controller. |

(1) Maintenance and repair of the robot must be performed by the personnel who was duly trained in the special maintenance training course and has a good knowledge of maintenance.

(2) Perform your work following the maintenance procedures for controller.

(3) Perform your maintenance and repair in a safe way by securing emergency exit or safe place.

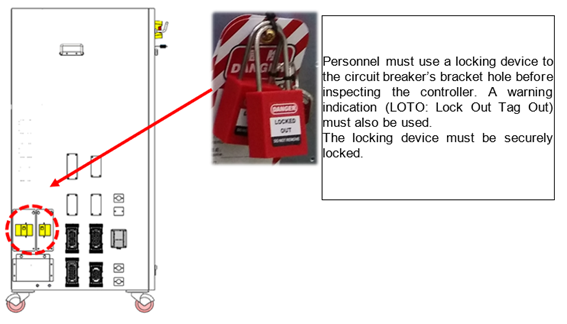

(4) Before the daily maintenance, repair, or changing parts, be sure to power down. In addition, post a warning sign [Do Not Input Power] up the primary power so that other operators may not input power by accident. For some controllers, such as C* series controllers, where a handle breaker–type circuit breaker is not used, a locking device must be used on the circuit breaker to prevent unauthorized power input by other workers.

A locking device for each line should be used if the motor and control power lines are separated.

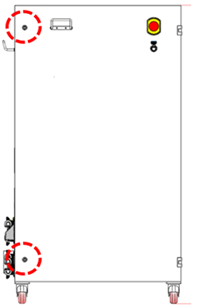

Check the locking devices and warning indication, and then unlock the locking devices (two locations on the front of the door) to perform maintenance. Authorized maintenance workers must manage the relevant keys.

In the case of products such as Hi5a-C* series models, where a handle breaker is applied to the motor power and a general breaker is used to control power, you must lock the general circuit breaker first and then open the handle to check the interior. This measure prevents power from being supplied to both input lines during the inspection.

(5) When changing parts, be sure to use the specified ones.

(6) When you open the door of controller, you should turn off power, and please start working after 3 minutes.

(7) If sufficient illuminance is not secured when you perform maintenance and inspection inside the controller, you should use external lights.

(8) Please do not touch heat radiating plate of servo AMP and recovery resistance because they are very hot.

(9) After completing maintenance, be sure to close the door completely after checking if tools or other things are still remained in the controller.

(10) Maintenance and inspection personnel should ensure that they participate in regular trainings and use the regulated specifications and tools for all types of assembly and wiring works in order to prevent defects from taking place.

(11) Training should be performed so that the operators can have sufficient knowledge of explosion-proof equipment. Moreover, training materials and records should be maintained.

(12) To verify the product, the operators should be skilled and their competence should be documented and adequately assessed.